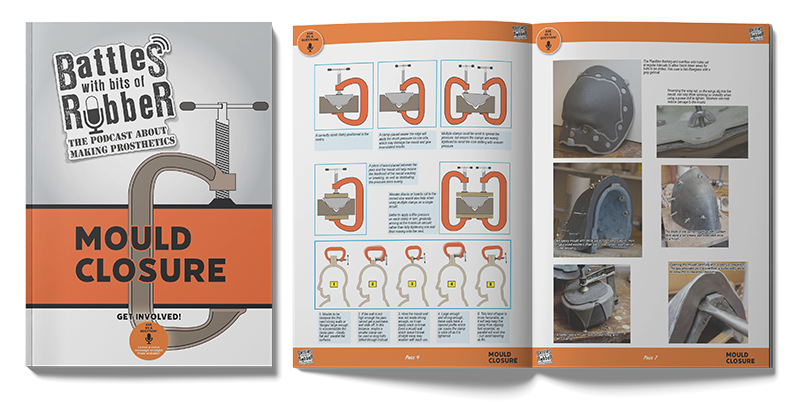

Closing moulds correctly is vital to get good casts out of them. There seems little point in making a good mould and then getting bad casts out of it.

In this episode, we take a look at things to consider in ‘mould closure’. Essentially, a mould other than a flat or open mould will usually need to be attached or fitted to another component to produce a cast.

To listen to the podcast, you can stream or download from here, or simply subscribe through your favourite podcast app – we are on many, including Spotify, Apple Podcasts, Soundcloud, IHeartRADIO , STITCHER , Luminary and Google Podcasts.

This could be another part of the mould if a ‘multi-piece’ mould is made and/or a core which will be placed into the mould to create the interior.

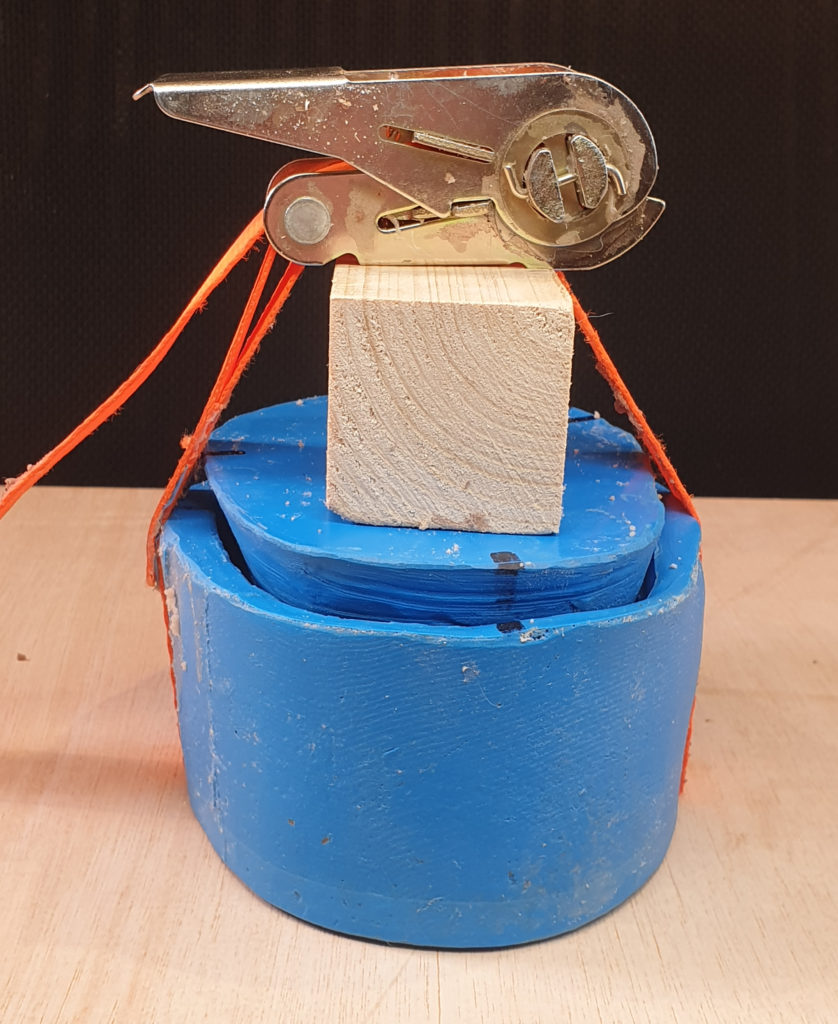

These pieces need to remain securely in position, and may be required to exert a lot of force if the cast piece needs to have thin seams which are more easily repaired.

That has cost implications – think about having to repair bad seams of fifty casts out of a mould which wasn’t closed correctly! Small block moulds are often clamped together for speed and convenience, but what happens if the mould is huge, such as a full body or a dinosaur?

Check out the notes included with this episode for a deeper dive with pictures.

In the podcast, Todd mentioned a cool gargoyle figure (pic below) that has an Oni demon style face that he was going to mould. We chat about risers to reduce the air bubbles that could be trapped in the mould, a common issue with smaller pieces with tight details.

Many thanks, as always, for your time checking the stuff out. You can email us directly at stuartandtodd@gmail.com or leave us a voice message on our site.

If you enjoy this podcast and got something out of it, would you do us a solid and tell just one more person about us? Send them a link and help us grow!

–Stuart & Todd

To listen to the podcast, you can stream or download from here, or simply subscribe through your favourite podcast app – we are on many, including Spotify, Apple Podcasts, Soundcloud, IHeartRADIO , STITCHER , Luminary and Google Podcasts.

Hi,

Just my 2 cents, I’ve taken apart wooden clothes pins and used them for wedges

when opening my epoxy molds. They work pretty well and are inexpensive.

Thanks

John

Hi John. That’s a great tip, thanks for sharing!!

-Stuart